High temperature synthesis

Many quantum magnets are oxides or halides that can't be grown from aqueous solution. One then has to resort to high-temperature synthesis and crystal growth. For that purpose we have several specialized furnaces and ancillary equipment. Some samples grown with this technique are on exhibit in our Gallery.

One of the simplest techniques is the Bridgman method, where crystals are grown from a melt. Appropriately chosen starting materials are sealed in a crucible, molten in the hot zone of a furnace, and very slowly translated through a well-defined downward temperature gradient. With luck, the material solidifies as a single crystal. Compounds such as Cs2CoBr4 are relatively easy to grow with this technique.

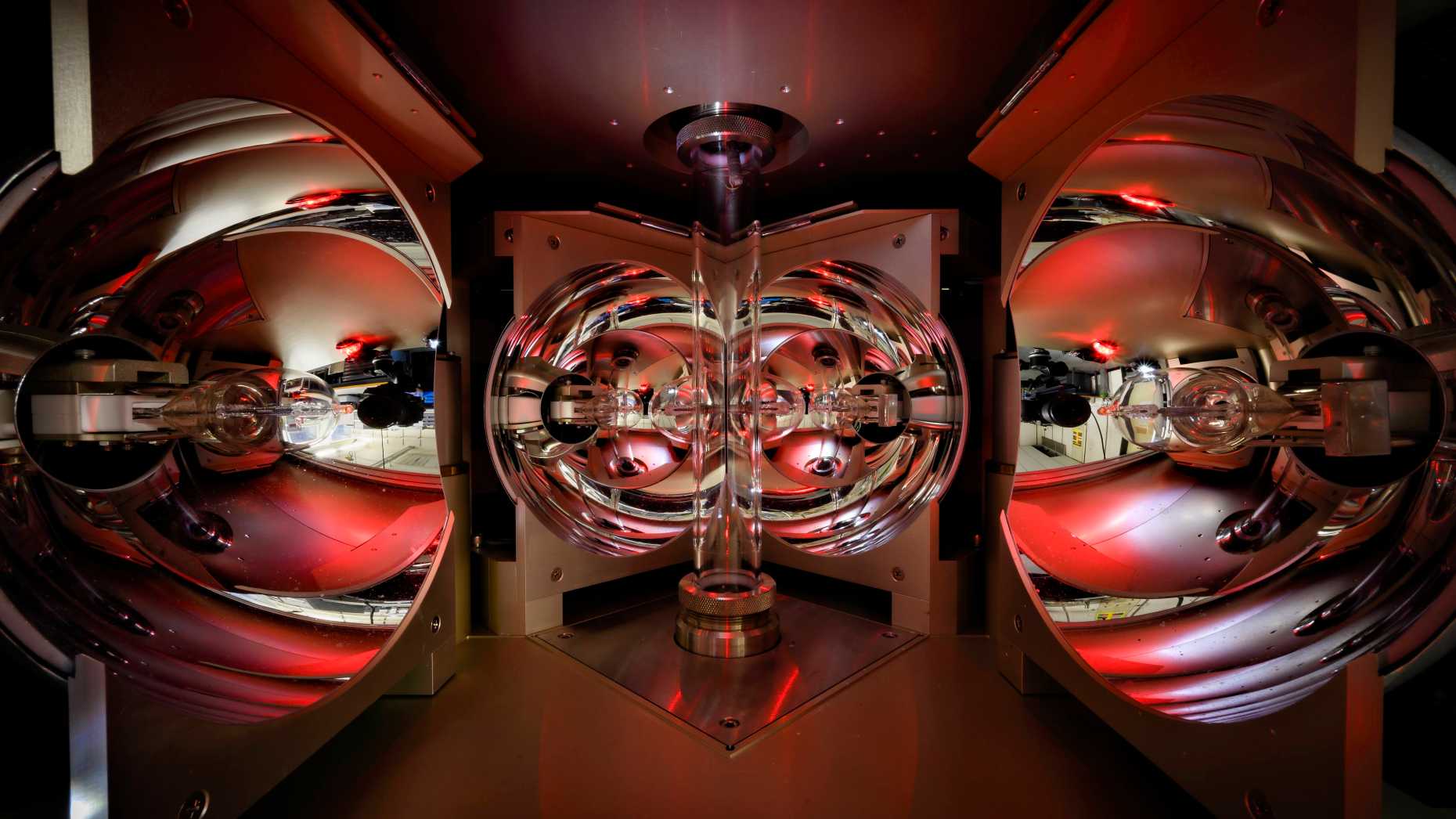

Another way to grow nice crystals employs an optical Floating Zone (FZ) furnace. This method avoids any contamination from using a crucible and can be used to produce large single crystals of complex oxides (cuprates, cobaltites, borates, manganates, orthoferrites), metals and other materials that melt at very high temperatures above 1000 oC. The technique first became popular in the 1990s, when it revolutionized the growth of high temperature superconductor compounds. In our lab we use a furnace with four elliptical mirrors to focus the heat generated by four halogen bulbs on a small spot on the sample. The gas atmosphere in the sample chamber can be precisely controlled. One application example was producing SrCu2(BO3)2 samples for our optical experiments.

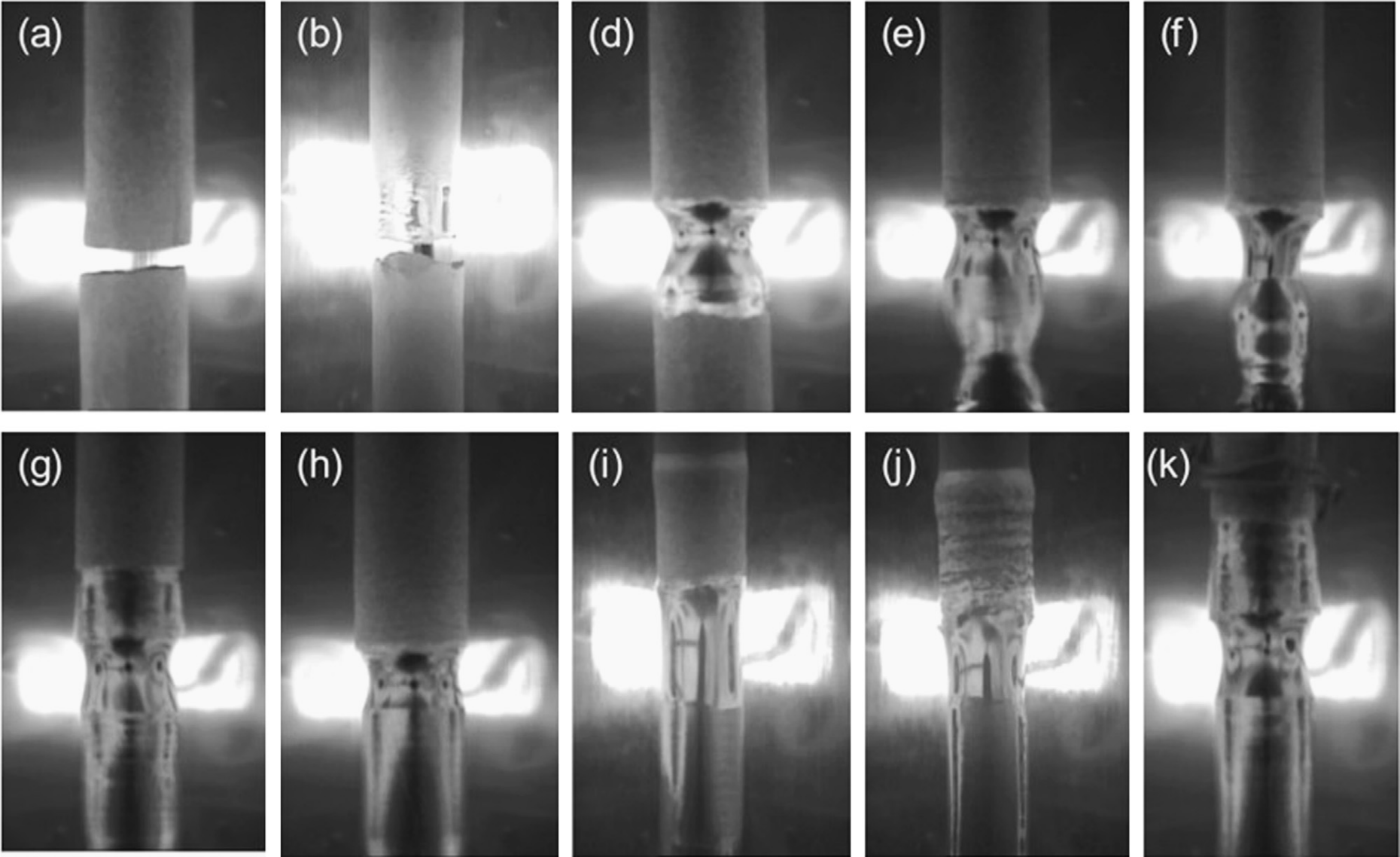

A pre-fabricated sintered polycrystalline feed rod is suspended from the upper shaft of a rotator device while a second seed rod is mounted on the lower shaft. Both rods are aligned co-axially. At the beginning, both rods are rotated in the same direction. The halogen lamps are powered up gradually until the lower end of the feed rod, which is located at the converged spot (see Fig. 1), melts as shown in Fig. 2(a) and (b). The feed rod is then lowered to connect to the seed rod in Fig. 2 (d). After the melting zone stabilizes, the rotation of the seed rod is switched to opposite to that of the feed rod. After a clear growth interface appeared, both rods start traveling downward through the convergence spot simultaneously. Most crystals are spontaneously nucleate in the melt without using a single crystal seed. After some "necking" and "shouldering" tricks a single growing crystal is selected as shown in Fig. 2 (e) to (k). As the rods travel through the melting zone, the crystal continues to grow.